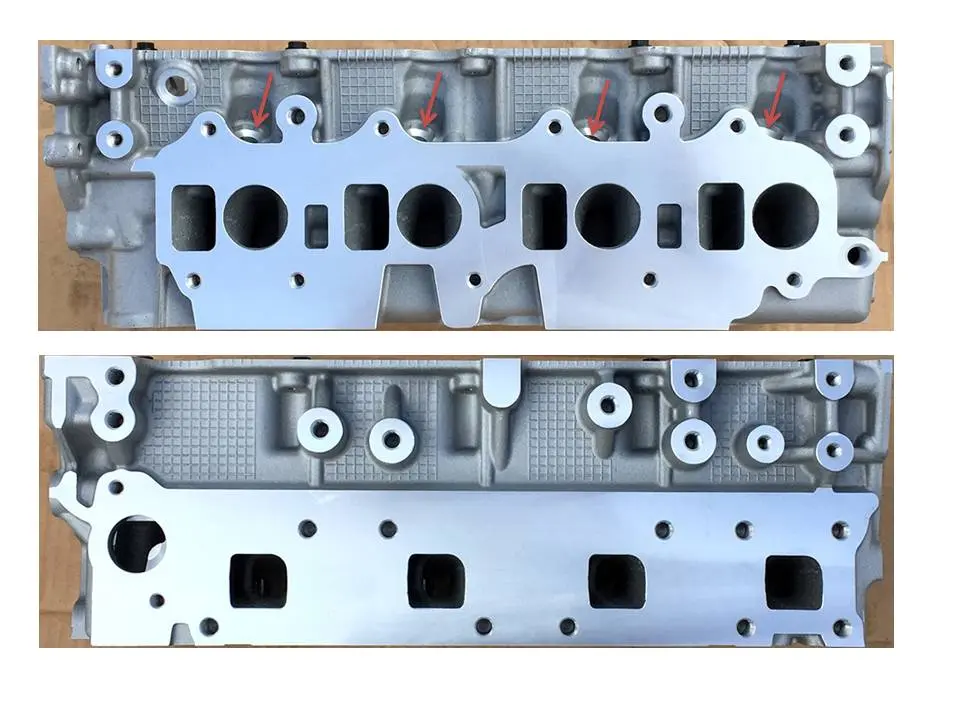

Nissan Cylinder Head YD25-C assembly 8 port late common rail type. Glow plugs on the inlet side. 171332

171332This YD25 cylinder head fits the later Nissan common-rail setup with the glow plugs sitting on the inlet side. The casting lines up with the 8-port layout, so it sits on the block without fuss and matches the original flow path. Most workshops use this head when the old one cracks around the injector seats or starts leaking after overheating. If you’re rebuilding a Navara or Pathfinder engine, this assembly gives you a clean base that supports proper sealing and steady running once everything is torqued down. A good choice when you want a head that fits right and keeps the job moving.

This cylinder head suits the Nissan YD25 common-rail engine 171332 in its later configuration—the one with the glow plugs sitting on the inlet side and the 8-port design. Mechanics often look for this exact layout because the earlier heads don’t sit the same way, and mixing types usually creates sealing issues. Here, the ports line up cleanly, and the mounting points match the later YD25 pattern.

If you work on these engines often, you already know where they fail. Most heads come off with cracks between the injector area and the pre-combustion region, or the surface warps after a heavy overheat. In those cases, repairing the old head doesn’t hold up for long, so replacing it is the safer route. This assembly helps you move forward with a rebuild without spending time trying to salvage damaged castings.

Another thing worth noting: the coolant passages and bolt holes sit in the right places, so the head fits the gasket properly. When you torque it down, it sits flat and keeps compression even across all cylinders. That’s important on the YD25, especially if you want stable idling and consistent firing under load.

This head works well for:

- Navara YD25 top-end rebuilds

- Pathfinder engine repairs

- Engines showing cracks, coolant mixing, or uneven compression

- Fleet maintenance where downtime matters

Most buyers choose this assembly because it lets them put the engine back together with confidence. It avoids the guesswork of reworking a damaged head and keeps the rebuild straightforward.

At Acme Impex, we check the casting finish, port alignment, and seating areas before dispatch. These checks help the head sit right during installation and support long-term operation when paired with proper torque settings and clean internal parts.

If you’re repairing a YD25 and want a head that fits the late-type setup without complications, this assembly is a solid option. It helps you finish the job cleanly and get the vehicle back on the road.